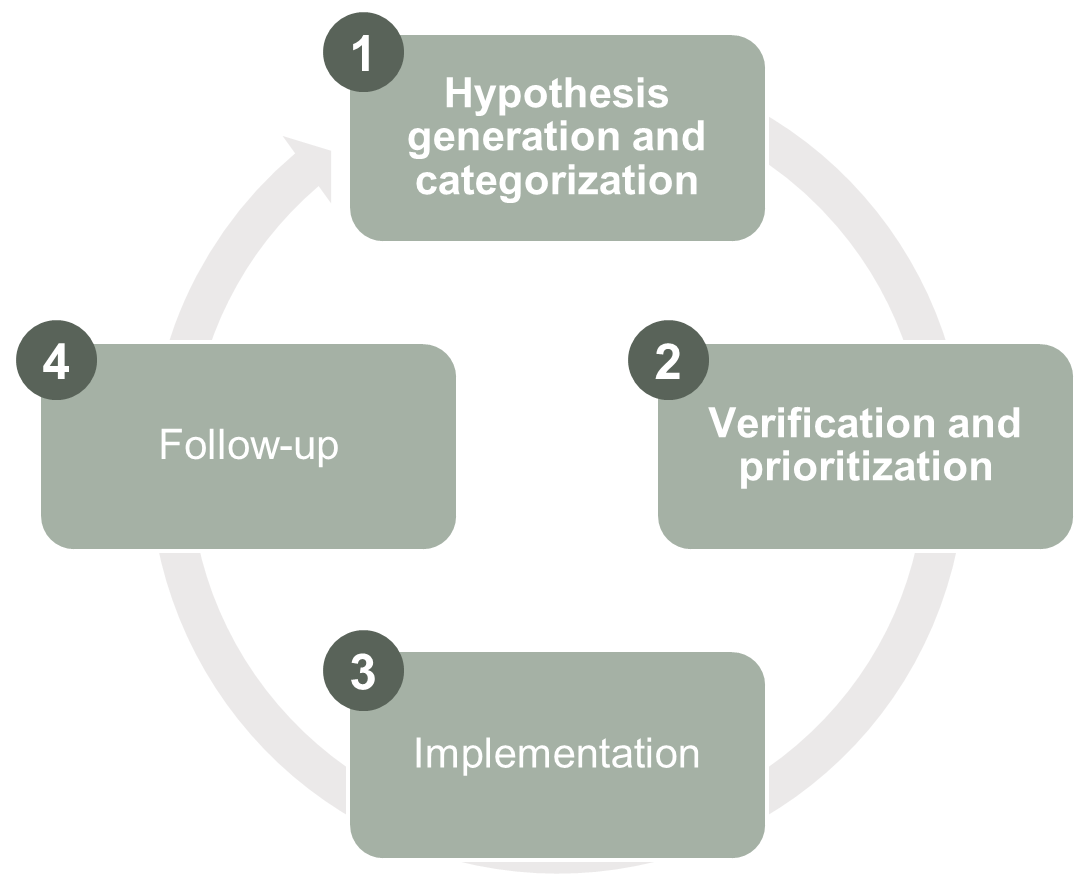

1. HYPOTHESIS GENERATION AND CATEGORIZATION

To facilitate Lean ways of working, a first practical step is to develop a framework for guidance. Start by identifying the company’s major cost drivers and apply four types of Lean actions to each of them – this will give you a useful framework for hypothesis generation.

The five types of actions that Axholmen uses when working with Lean are:

- More efficient processes (consolidate, educate, eliminate etc.)

- Smarter purchasing (competitive tendering, preparation, commercial models etc.)

- Exploit spare capacity (increase sales with the same costs etc.)

- Increased operational control (e.g. KPIs to charge the right amount for value created)

- Reduced risk through increased share variable costs

Interview key people in your organization to get an understanding of where to find the improvement potential and what kind of initiatives are of interest. An effective technique is to start with a blank piece of paper and think about how someone would have conducted a process or activity if asked to do it today. The list of hypotheses quickly gets long, so create a structured document to categorize and track the progress of your initiatives.

2. VERIFICATION AND PRIORITIZATION

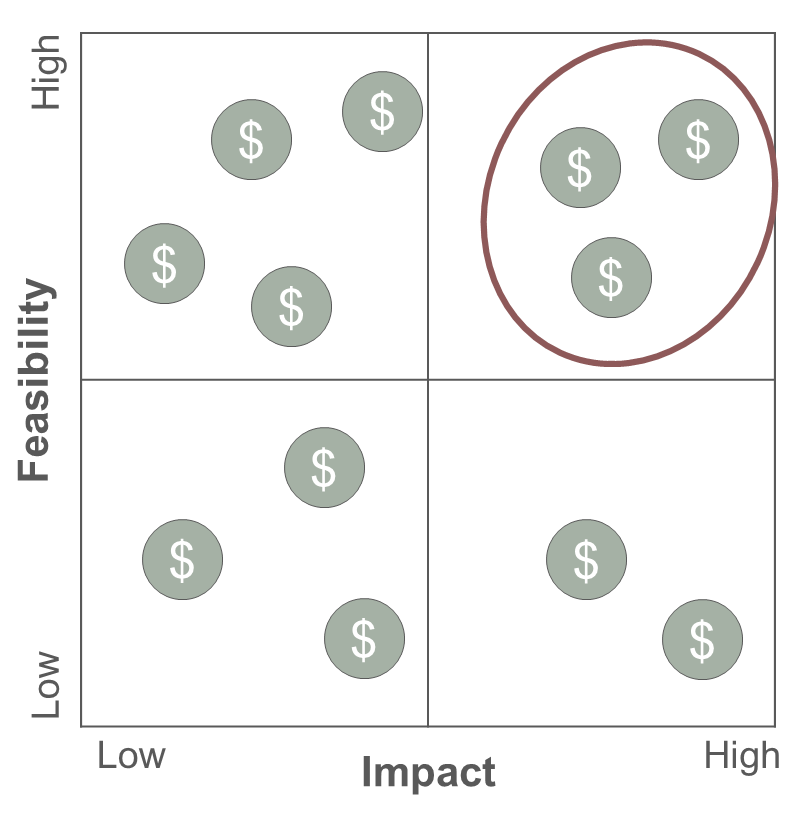

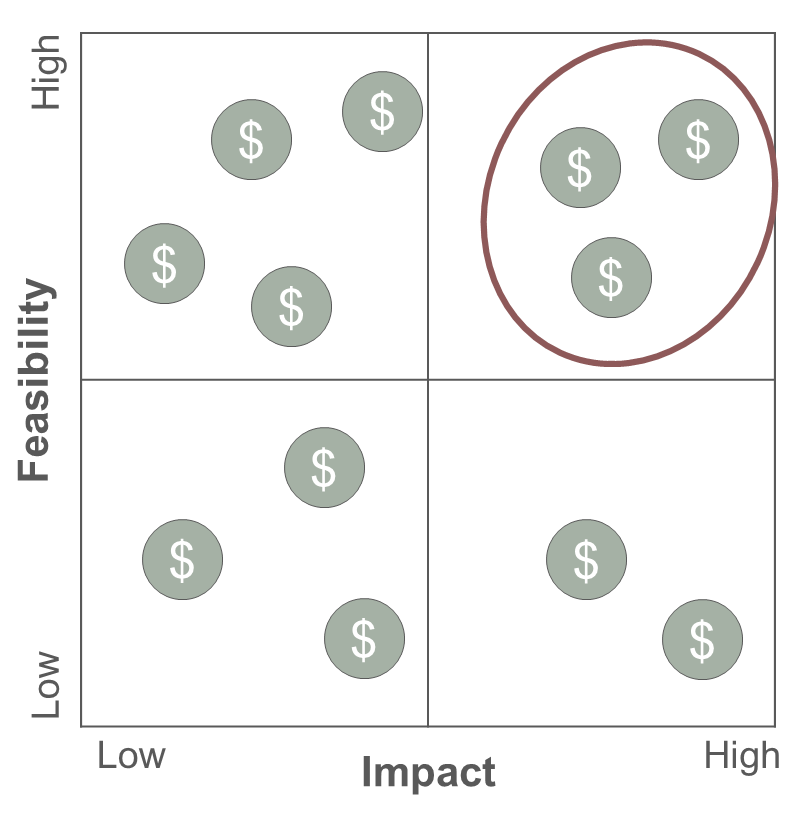

Since resources always are limited, you have to prioritize you among your hypotheses. Start by quantifying the expected impact of each initiative. You then need to understand both the amount of work required and the likelihood of a successful implementation.

Highest priority is given to the initiatives with highest potential impact and feasibility (see Figure 2). Always verify the potential impact and feasibility with initiative owners and set shared targets for each initiative. Make sure to have well-documented decision material ready if the implementation decision is to be made further up in the organization.

Figure 2: Prioritization tool for hypotheses

3. IMPLEMENTATION

The owner of the initiative, who has verified and decided on the initiative, must support the implementation and to some extent be involved. In order to create a good work balance, other people should be involved who can reduce burden for the initiative owner. To achieve lasting results and create ownership, you want to involve the people who will be affected by the change as early as possible in the implementation. In many cases, these people can also provide important input. Communicate “success stories” on an ongoing basis and highlight individuals who have made an effort to generate interest in Lean. If you have worked in a project form, there should be a clear handover to the line organization before an initiative is considered complete.

4. FOLLOW-UP

Evaluate the changes made after implementation and make necessary adjustments. Listen to the people working in the affected areas, if they are satisfied the change will be permanent. You can’t control what you don’t measure. By continuously quantifying and monitoring the results and comparing against the previously set targets, you will learn what types of initiatives work for your business. Be pragmatic about the follow-up, it shouldn’t be too time consuming.