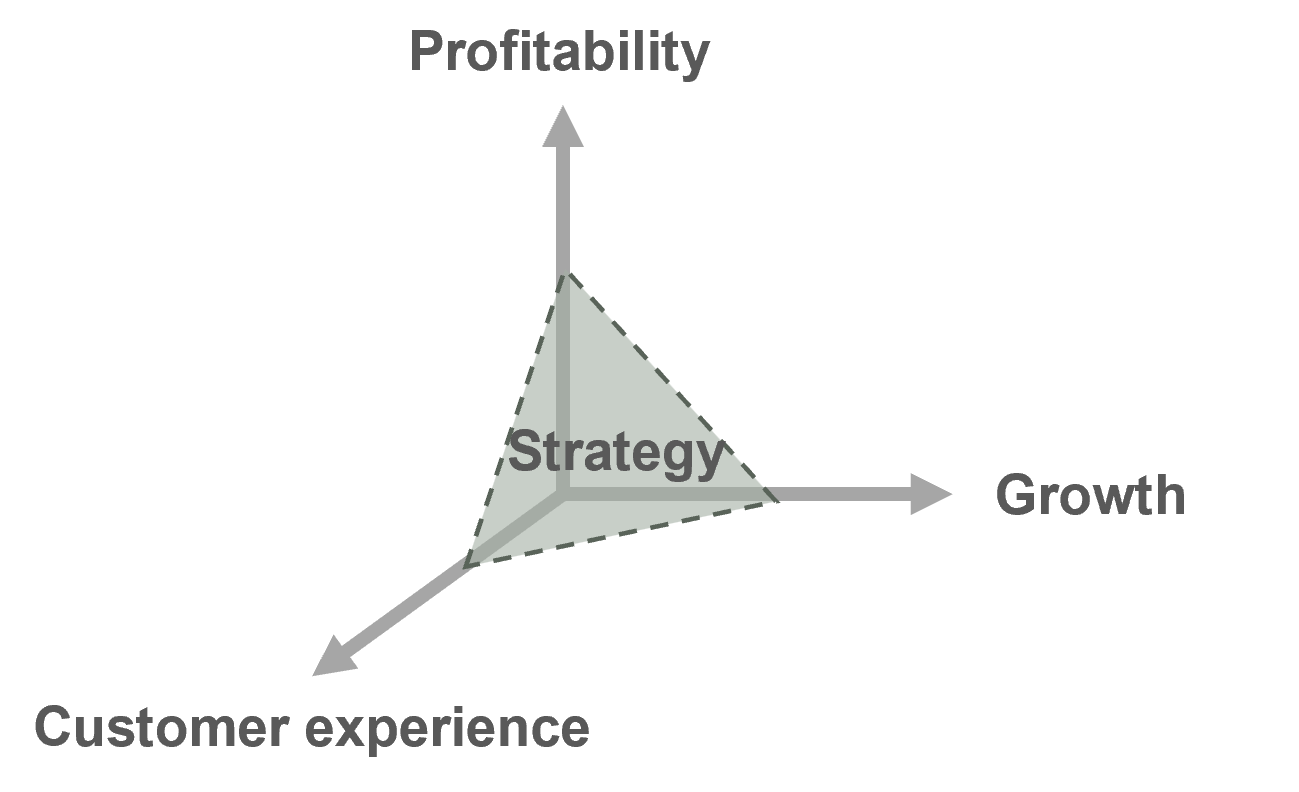

1. LOOK UP – ALIGN THE SUPPLY CHAIN WITH YOUR COMPANY’S STRATEGIC GOALS

Translate company strategy into requirements for the supply chain function: what should be the priority – growth, profitability or customer experience?

Is the supply chain function adapted to:

- support the growth plan for new products and geographic markets?

- maintain profitability with increasing volumes in multiple channels?

- meet customers’ increasing demands for fast and reliable deliveries?

For example, plan early for future sales volumes and adjust the emphasis of the supply chain platform accordingly. Furthermore, geographical distances and differences in wage levels can have a major impact on both profitability and growth. For example, before sufficient volumes are achieved in a new geographical market, collaborations with an external partner to manage warehousing and distribution can reduce risk. However, the basic principle should be to centralise warehousing and distribution in order to benefit from economies of scale and lower distribution costs.

2. START SIMPLE – BUT CREATE THE RIGHT CONDITIONS FOR INCREASING VOLUMES

It’s easier to get it right the first time. Once volumes take off, complexity increases dramatically and deviation management can quickly become overwhelming. Remember:

- Streamline flows by, for example, separating return handling and removing deviation handling from the regular flow

- Define clear processes and create the conditions for efficient inventory management by, for example, registering weight, volume and complete article description right from the start

- Choose simple solutions – e.g. barcode labels for item identification can be a cost-effective alternative to more complex RFID solutions

- Strive for flexibility and therefore carefully consider the business case for investing in automated warehouse systems. What is the investment horizon? How long will the warehouse remain in its current location? Are the volumes sufficient and the assortment predictable and suitable for automation?

3. COLLABORATE ACROSS FUNCTIONS – CREATE A BUSINESS-ORIENTED SUPPLY CHAIN FUNCTION

A business-oriented supply chain function that collaborates with other functions in the company can contribute to profitable growth in a number of ways:

- Increasing conversion rates through differentiated delivery methods and the right product in the right place at the right time – a challenge that is becoming increasingly complex with more channels and stock points

- Satisfied customers through reliable information and properly handled and packaged products

- Increased profitability: by allocating costs to actual cost drivers such as storage, handling, distribution and return rates, the right sorting decisions can be made and product profitability increased

- Control of capital commitment: by optimising inventory levels, capital can be freed up for other purposes. For example, through a proactive process for outgoing items, promotions can lead to both a reduction in capital tied up and a lower need for write-downs – which also reduces the risk of boxes reaching the ceiling